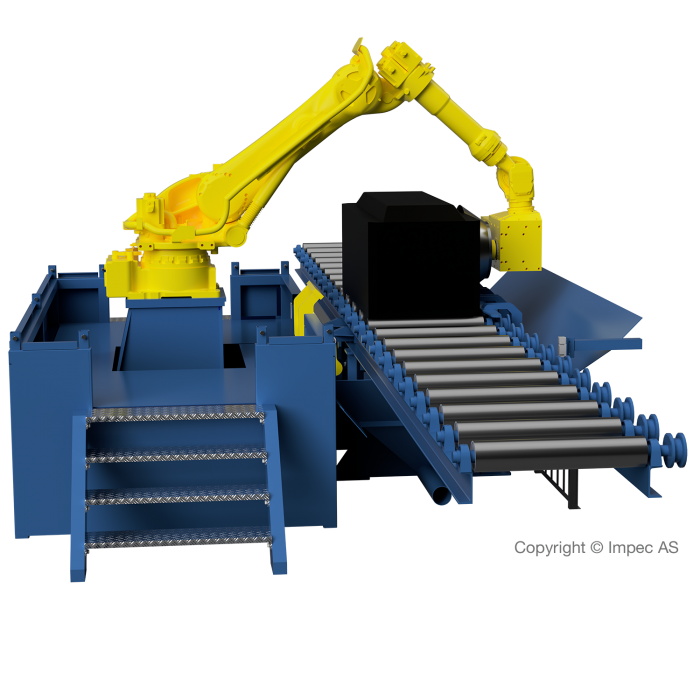

Robotic anode cleaning system

Carbon

Our robotic anode cleaning system consists of two separate units.

- One robot for mechanical brushing

- One robot for milling

The system in combination with anode recognition is fully automatic and customizable for multiple different anode types.

Brushing station removes “loose” packing material from the anode surface left on anode after baking in kiln. Milling station cleans the anode by use of a specially designed milling tool without removing material from the anode itself. Packing coke burned into anode surface is removed and anode can be returned to production line instead of recycling.

Reference:

Hydro Aluminium Årdal